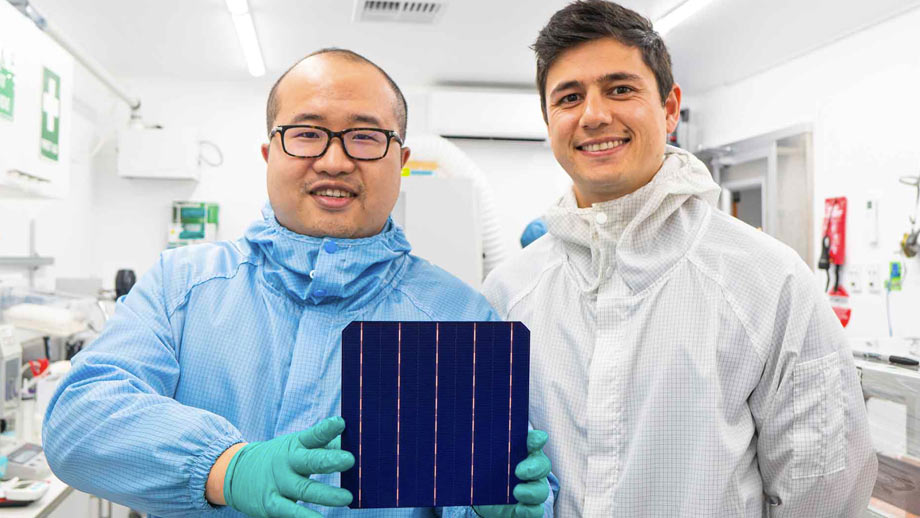

An Australian startup, SunDrive, has not only produced the world’s most efficient solar cell, but they’ve also slashed costs by replacing silver with copper in the cell’s production.

The team, based in South Sydney, had their innovative solar technology tested by the German Institute for Solar Energy Research (ISFH), and last week received the news that they’d bested previous records for the efficiency of a commercial-size silicon solar cell with a score of 25.54%.

Chinese manufacturers have led the way in recent years, but with this result from a small local team, there is renewed energy around the potential for solar manufacturing to come back to Australia.

This potential didn’t go unnoticed by the government with the Australian Renewable Energy Agency (ARENA) offering SunDrive $3 million in funding late last year. It aimed to advance the technology from an industrial sized cell to a commercial size module, as well as developing a small scale automated production line prototype.

“It’s fantastic to see an Australian solar startup at the forefront of producing the next generation of high efficiency solar cells. Through technological innovations from startups like SunDrive, Australia will remain at the forefront of solar innovation and research and development for years to come.” ARENA CEO Darren Miller said at the time of the announcement.

The funding round also saw the teams raise an additional $5 million from Blackbird Ventures and Mike Cannon-Brookes’ Grok Ventures.

And prior to that they received their first angel investment from UNSW alumnus Dr Zhengrong Shi, founder of solar power heavyweight SunTech.

The team has a long way to go. The Chinese manufacturers who were the previous leaders in solar cell technology had already negotiated a path to commercialisation and manufacturing, selling billions of dollars worth of panels per year.

On the other hand, SunDrive is yet to sell any final product, but they have shown remarkable promise, managing to engineer a solution to a problem that’s vexxed engineers for decades, in a suburban garage.

By replacing silver with copper in the production of the cells, production is simpler and far cheaper. It’s estimated that solar cell production uses 20% of the world’s supply of silver.

Currently, solar power produces less than 5% of the world’s electricity. If we’ve any hope of that figure rising dramatically, to materially replace coal in power generation, then efficiency needs to rise and costs need to come down.